Highlights

- Google’s Agent2Agent (A2A) protocol lets AI agents communicate with each other, share tasks, and work across platforms, so AI in logistics and supply chain is not stuck in one tool.

- Most AI agents in logistics sit in silos from different vendors, which doesn’t help to rectify delays, missed signals, and manual work across warehouses, and fallbacks of fleets, and planning.

- With A2A, those walls drop. Agents sync, act faster, and help supply chains run smarter.

Remember how in 2024, Volvo and DHL Supply Chain launched driverless freight trucks in Texas?

This breakthrough showed just how fast AI is changing logistics, bringing new speed and efficiency to everyday operations.

Yet, even with these leaps forward, there’s a hidden problem.

AI agents are helping logistics companies optimize warehouses, streamline delivery routes, and forecast inventory needs faster than ever before.

But most AI agents today work in silos — isolated, unable to collaborate across systems.

This fragmentation limits the true power of AI.

In industries where every second counts and margins are tight, disconnected agents slow decisions, duplicate efforts, and miss opportunities.

Google’s Agent2Agent (A2A) protocol — already being called the "HTTP for AI agents" promises to unlock a future where AI systems don’t just work harder, but work smarter, together.

In this blog, we’ll explore what A2A means for the logistics and supply chain sector, why it matters for your business, and how early movers could gain a serious edge in the years ahead.

How silos are holding back AI in logistics and supply chain innovation

AI has done a lot for logistics already.

It helps:

- Forecast customer demand to avoid overstock and stockouts

- Manage warehouse picking and packing with smart robots and automated systems

- Plan trucking and shipping routes for faster, cheaper deliveries

- Predict maintenance needs to reduce equipment downtime

- Optimize inventory levels across multiple warehouses

- Track shipments in real time and flag delays early

But here's the problem:

These AI systems usually don’t talk to each other.

Why?

Because most AI tools are built separately, by different vendors, using different rules, and without a common way to share information.

The result?

Even smart systems end up working in isolation. This leads to delays, missed signals, manual handoffs, and slower decision-making — exactly the things logistics businesses can't afford today.

Imagine these:

- A warehouse finishes packing early, but the trucks aren’t rescheduled.

- A demand forecast spots a spike in sales, but inventory doesn’t adjust fast enough.

Even today, people still have to step in — sending emails, making calls, double-checking systems.

Without AI agents working together, logistics companies are leaving speed, efficiency, and profit on the table.

And in a world that’s moving faster every day, that’s a serious risk.

Revolutionizing logistics and supply chain automation with A2A

A2A changes everything.

It’s an open protocol that allows AI agents to discover each other, communicate securely, delegate tasks, and collaborate across different vendors, systems, and cloud platforms — all without custom coding or complicated integrations.

Better yet, A2A is designed to work with major enterprise systems like SAP, Salesforce, Oracle, and more, making it easier for businesses to build connected, intelligent operations without starting from scratch.

Why the A2A protocol is key to logistics and supply chain automation

- No more vendor lock-in. Agents can collaborate across different software systems.

- Built-in security and governance. Sensitive logistics data stays protected.

- Faster decisions. No waiting for humans to connect the dots.

The shift is happening fast.

Applications of A2A (AI) in logistics and supply chain

Here’s how A2A is already opening up new possibilities:

1. Real-time route and delivery optimization

Traffic-monitoring AI agents can work with fleet-management agents to reroute deliveries dynamically. Weather AI agents can alert shipping agents early, helping avoid costly delays.

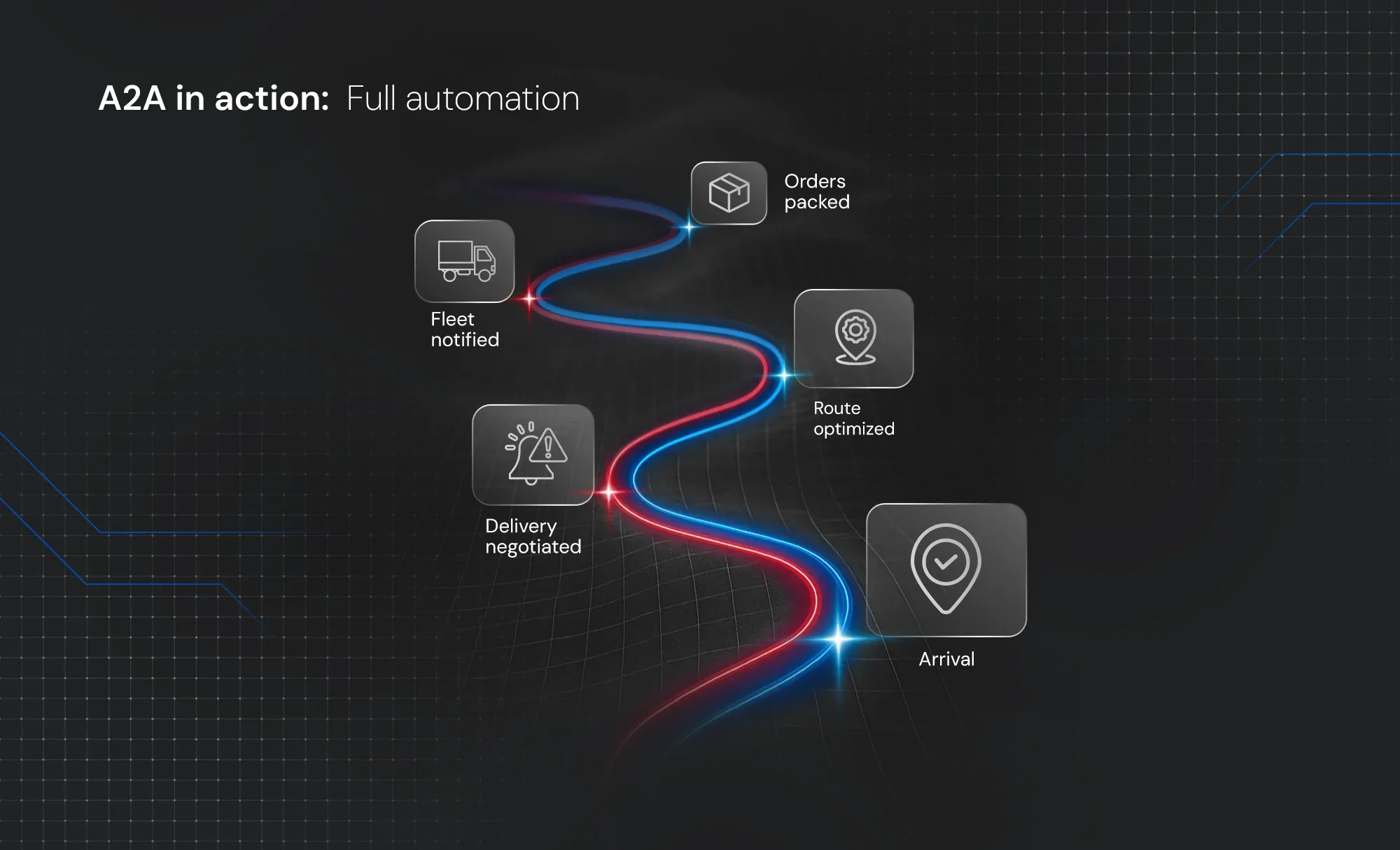

2. Warehouse-to-fleet coordination

Today, once an order is packed, warehouse teams often have to call or email for truck dispatches.

With A2A, as soon as a robot picks the last item, an AI agent can automatically alert the fleet system and schedule pickup — instantly.

3. Autonomous freight negotiations

AI agents representing carriers and shippers can negotiate pricing, timelines, and contracts in seconds.

4. Disaster relief and emergency logistics

In disaster zones, relief coordination agents, transport agents, and inventory agents can collaborate instantly — ensuring aid gets where it’s needed without chaos or delays.

Real-world impact of A2A AI in logistics and supply chain

Imagine a major retailer’s warehouse in Texas.

When an item’s stock runs low, a procurement AI agent automatically reorders.

A logistics agent schedules faster shipping.

A warehouse agent prepares for early arrival.

All without a single human manager needing to intervene.

That’s the future A2A protocol is making possible.

Future predictions: Where A2A is heading

Looking ahead, A2A is expected to reshape the entire supply chain landscape.

Experts predict:

- Self-adjusting supply chains that reroute goods automatically if problems arise.

- Autonomous freight networks where AI agents handle bookings, contracts, and rerouting without human delays.

- Smart warehouses where picking, packing, and dispatching happen with real-time, agent-to-agent communication.

The shift is already in motion. The companies that start building with A2A today will be the ones setting the pace tomorrow.

If you are looking for a partner to engineer your next million-dollar idea, KeyValue has 9+ years of experience building 130+ world-class products globally.

So, let's build your next? Contact us!

Building the future of logistics, one agent at a time

Logistics has always been about speed, precision, and staying one step ahead.A2A enables AI agents the tools to work together and helps businesses operate smarter, faster, and more efficiently than ever.

The businesses that move early will shape the next generation of supply chains. The rest may find themselves struggling to catch up.

If you're thinking about future-proofing your operations, now is the time to start exploring agent-based solutions.

At KeyValue, we help logistics and supply chain businesses unlock the power of AI, automation, and next-generation technologies like A2A — so you’re ready for what’s next.

The next wave of logistics innovation is already here.

Let’s build it together.

FAQs

What is A2A (Agent2Agent) in logistics?

It is an open protocol from Google that lets AI agents discover each other, talk securely, hand off tasks, and work across different vendors, systems, and clouds without heavy custom code. This makes it easier to build connected AI in logistics and supply chain solutions.

Why are today’s AI agents not enough for supply chains?

Most are built by different vendors and do not share data in a common way, so even smart systems stay in silos. The result is delays, missed signals, manual calls and emails, and slower decisions across warehouses, fleets, and planning tools.

How does A2A help fix logistics and supply chain AI silos?

By giving agents a shared way to communicate and delegate work, A2A lets warehouse, fleet, demand, and other agents sync in real time. That means fewer manual handoffs and faster moves when conditions change.

Will A2A protocol work with the systems I already use?

Yes. It is designed to plug into major enterprise platforms such as SAP, Salesforce, Oracle, and others, so you can extend AI in supply chain and logistics without starting over.

What are some early A2A use cases in logistics and supply chain

Dynamic route and delivery changes using traffic and weather data, warehouse to fleet auto scheduling when orders are packed, carrier shipper rate negotiations by agents, and fast disaster relief coordination are all examples in the blog.

What benefits can I expect?

Less vendor lock-in, stronger security and governance for sensitive freight data, and faster decisions because agents share context instead of waiting for people to connect tools.

What could A2A mean for the future of AI in logistics and supply chain?

Think self-adjusting supply chains, autonomous freight networks that book and reroute on their own, and smart warehouses that pick, pack, and dispatch through agent-to-agent coordination. Early adopters will set the pace.

How do I get started with implementing A2A in logistics and supply chain operations?

If you want to future-proof operations, now is the time to explore agent-based workflows. KeyValue helps logistics teams apply A2A, AI, and automation so you can move faster and stay ready for what is next.